GEC-Solutions offers customized solutions in the fields of engineering, consulting and interim management for mechanical and plant engineering. With technical expertise, strategic vision and management experience, I support companies – from technology development to process optimization.

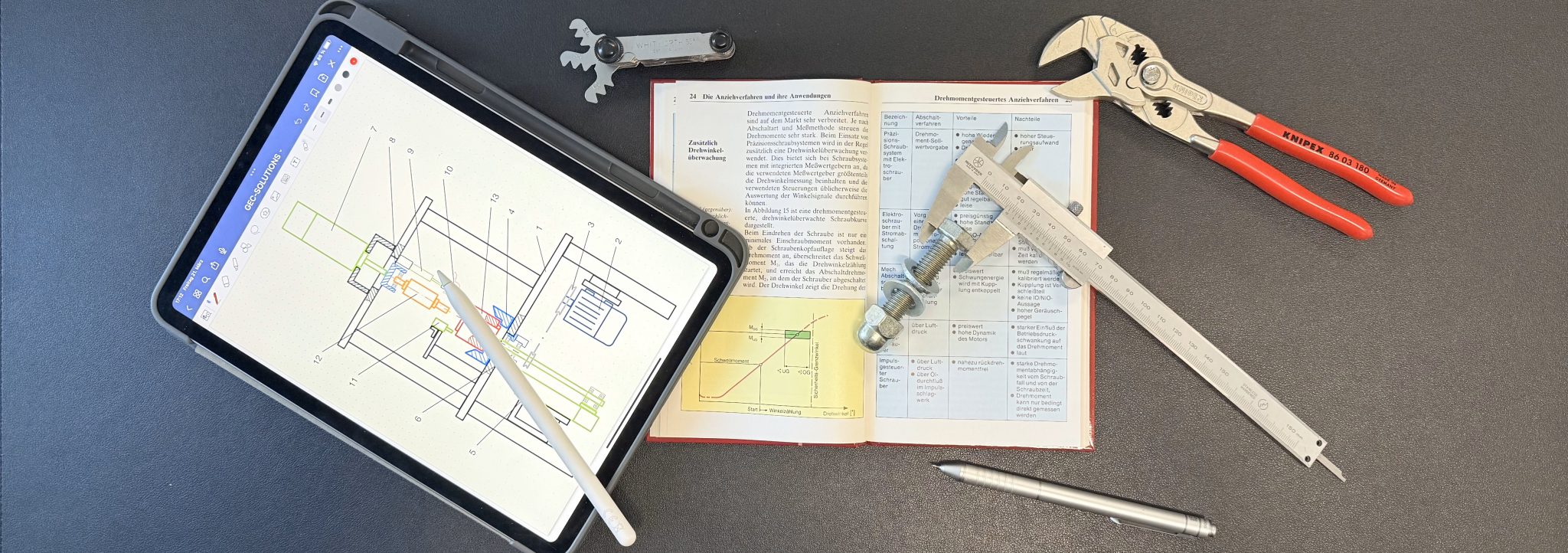

Engineering

- Development and optimization of special machines and automation solutions

- Analysis and improvement of manufacturing and assembly processes

- Introduction of innovative technologies to increase efficiency

- Technical project management – from the concept phase to commissioning

- Concept development, feasibility studies

- Preparation of calculations and quantity structures

- Supplier evaluations, selection and inquiries

- Cycle time calculations, creation of flow charts

- Design and verification of shaft lines to minimize torsional vibrations

- Layout planning

Consulting

- Process analysis and strategic realignment in mechanical engineering

- Analysis and improvement of manufacturing and assembly processes

- Creation of functional and requirement specifications as well as specifications

- “build or buy” consulting

- Sales and business development for sustainable growth

- Patent creation and innovation management

Interim management

- Assumption of management positions (CEO, COO, CTO)

- Assumption of technical management positions (site and plant management, sales management, design management, production management)

- Restructuring and optimization of business areas

- Building and leading high-performance teams

- Support for transformation and M&A projects

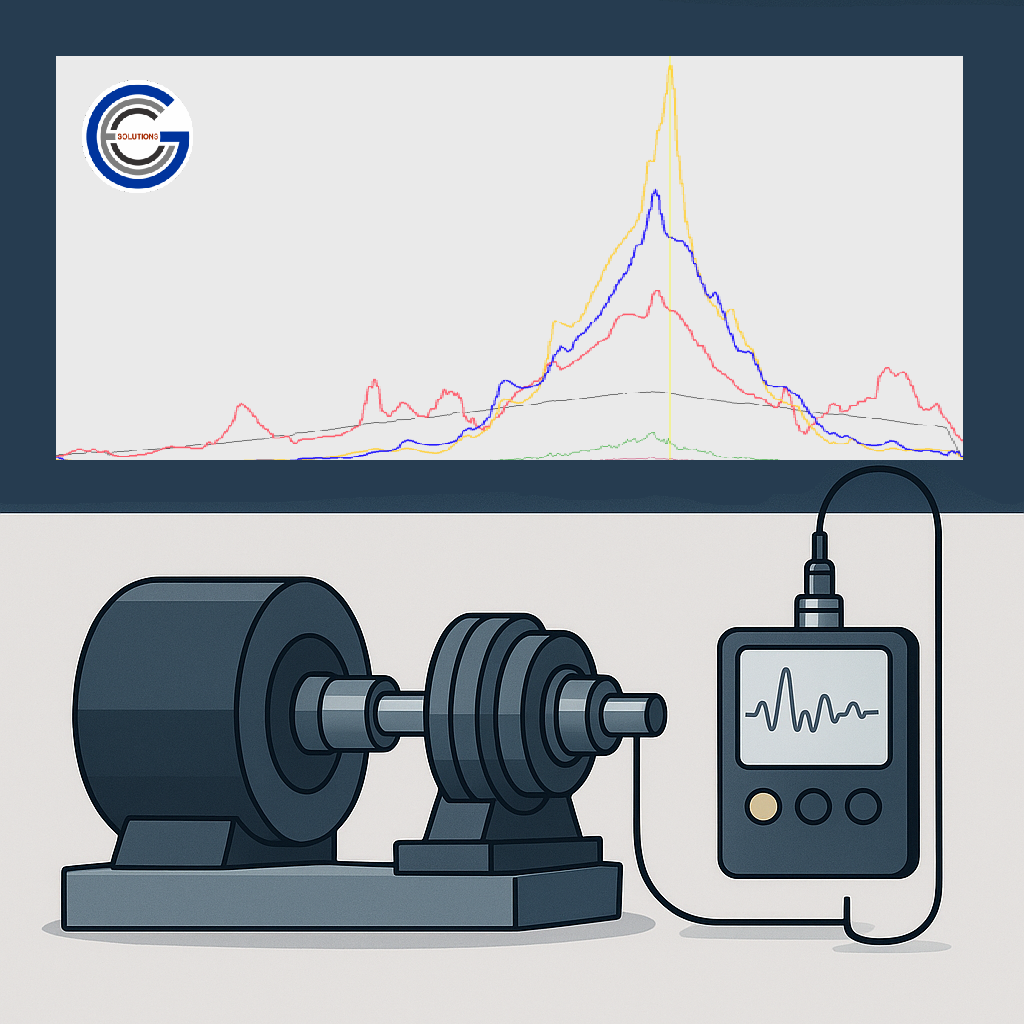

Vibration-measurement / Vibration-analysis

- On-site problem assessment

- Vibration analysis

- Modal and natural frequency analysis

- Torsion analysis

- Rotational vibration measurement

- Balancing

- Developing proposed solutions

- Reporting

Unwanted vibrations in machines and test systems can lead to malfunctions, quality problems, and increased wear. Using modern measurement and analysis methods, we identify the causes, such as imbalances, resonance phenomena, or speed-dependent vibrations, and develop appropriate measures to reduce them.

Our services range from vibration analysis on test bench shaft lines to on-site balancing work and torsion and resonance analyses.

The result is a well-founded assessment of the machine condition, including specific recommendations for action to optimize and ensure reliable operation.

We can also take care of implementation on request.

It is not always possible for customers to implement recommendations for action themselves. In such cases, we are happy to support you and reliably implement the necessary measures – from design changes, calculations, and layout to the selection and procurement of necessary components. Our range of services also includes the manufacture of machine parts, adjustments to the test bench, including extended commissioning, and updating of machine documentation.

This means you receive everything from a single source: from analysis to practical implementation.

More Information: https://gec-solutions.de/Vibration-measurement/

International Trade Support

Market entry support

- Consulting and support for entering the German and European markets

- Support with standards, approvals, and regulations (e.g., CE, DIN, TISAX)

- Establishment of local sales and service networks

- Preparation and support for trade fair appearances and customer acquisition

- Support with location selection, logistics and import processes

- Access to my international network (China, Europe, USA)

→ Goal: Fast and successful market entry from day one

International procurement and export support

- Procurement of high-quality components and technologies from Europe

- Technical clarification and comparison of customer specifications

- Selection of suitable manufacturers and solicitation of quotes

- Organization of purchase, export, and delivery to the destination

- Quality inspection and documentation prior to shipment

→ Optional: Complete processing as a one-stop solution

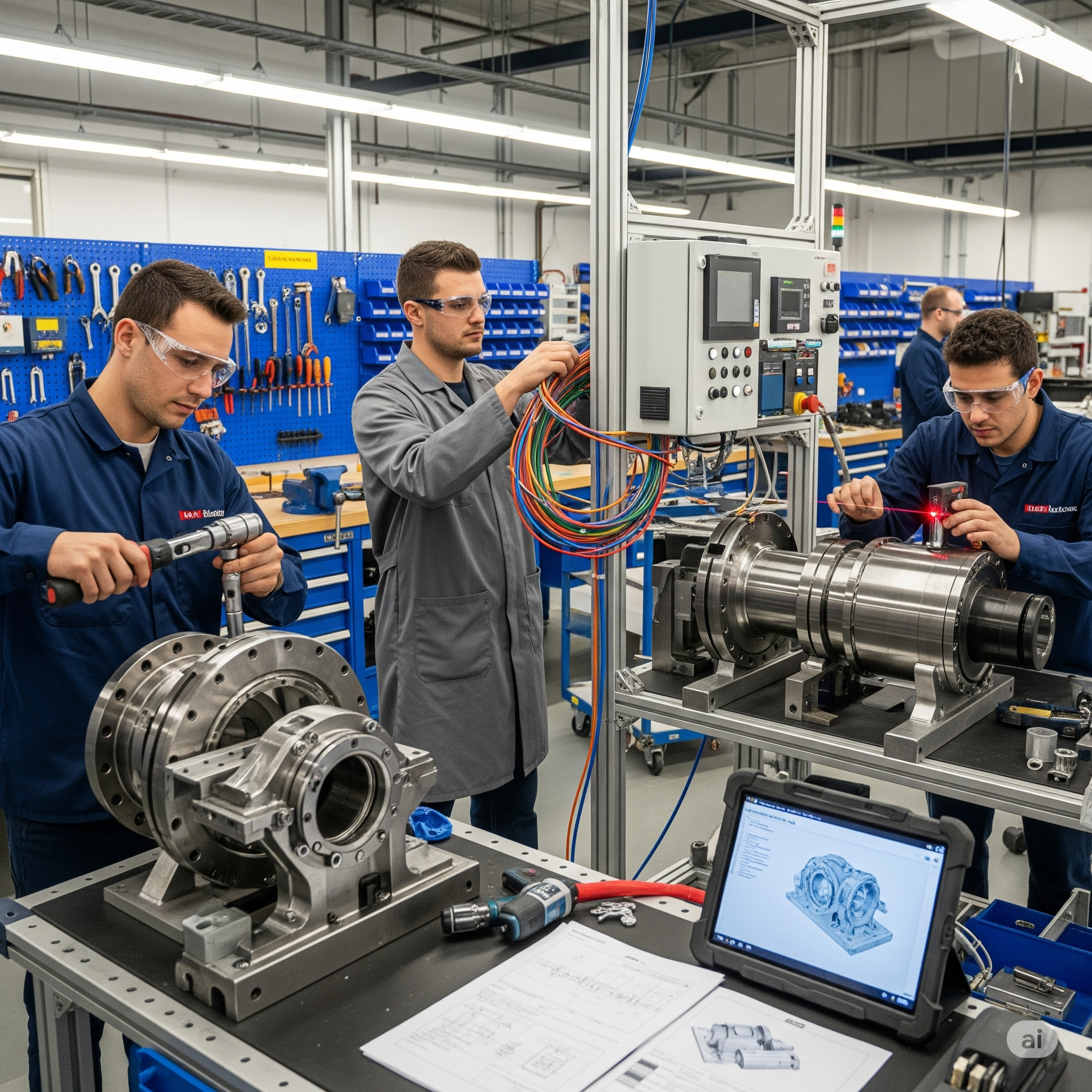

Services

Individual part production

- Production of prototypes and individual parts according to customer requirements

- Assembly production

- Flexible small series production

- Quality testing and dimensional control

Assembly

- Assembly of complete assemblies and special machines

- Mechanical and electrical integration

- Alignment work including documentation

Repair service

- Troubleshooting and diagnosis in the event of failures

- Replacement of defective components

- Retrofitting and modernization of existing systems

Commissioning (PLC-based)

- PLC programming and commissioning of machines and systems

- Adaptation and optimization of control systems

- Functional tests and acceptance at the end customer’s premises

- Fault analysis

GEC-Solutions – your partner for sustainable solutions in mechanical and plant engineering.